A. Adjust the swing joint to level the top surface of the rotor body with the finished grade. Backfill the area around the body with sand for proper drainage and tamp down the soil to prevent settling.

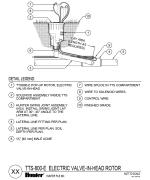

B. Solenoid and two-way module connections are designed to be made inside the flange compartment using DBRY-6 waterproof connectors.

C. Leave enough slack in the wire to make any needed future adjustments.

D. All models have 1½" (40 mm) Acme threaded inlets. Do not use NPT or BSP threaded fittings to connect TTS-800 rotors. Adapters are available to attach NPT or BSP swing joints to Acme threads.

E. Rotate the TTS-800 rotor body clockwise to tighten by hand until it bottoms out. Then unwind a half-turn to allow for minor adjustment after installation. Acme threaded inlets come with an O-ring to create a seal. Do not use Teflon® tape, PVC cement, or other thread sealant to connect as these products can deteriorate the fitting and cause leaks.

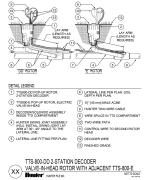

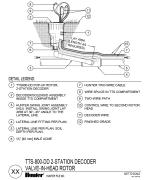

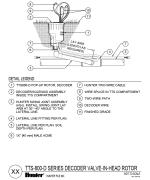

Wiring Diagram

The diagrams below illustrate wiring connections for two-way module and conventional systems.

Still need help? We're here.

Tell us what you need support with and we'll find the best solution for you.