Al instalar el kit, es fundamental preparar correctamente la ubicación de la tubería de entrada. Si se hace correctamente, usted debe ser capaz de nivelar con facilidad la turbina utilizando la cantidad predeterminada de conexiones.

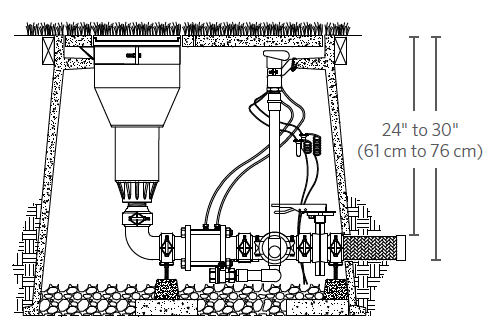

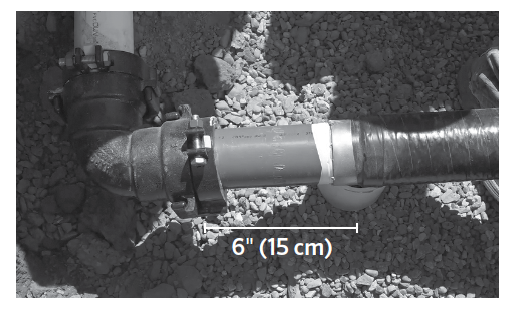

El primer paso consiste en preparar la profundidad y la ubicación de la tubería rígida conectada a la entrada del colector. La entrada del colector debe estar centrada a lo largo de la pared lateral de la arqueta, aproximadamente a una distancia de entre 24" y 30" (61 cm a 76 cm) de la parte superior de la arqueta. Aunque este es el ángulo estándar para el colector, puede bascular dentro de la arqueta. Esto permite ajustar pequeñas variaciones angulares en la tubería secundaria rígida que se conectará al colector. La línea principal también debe fijarse a esta profundidad aproximada, a menos que se especifique otra cosa. Una vez que se conozca la ubicación de la línea de suministro de agua de entrada y de la manguera flexible en relación con el colector, utilice una sierra de corona de 6" (15 cm) para hacer una abertura de acceso en la pared lateral de la arqueta.

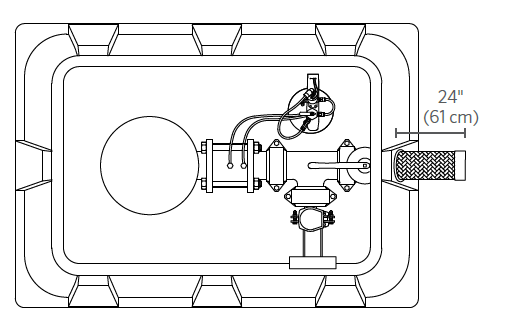

Por último, es importante tener en cuenta que el manguito flexible de acero inoxidable se extenderá 24" (61 cm) desde la arqueta hasta la línea principal. El tubo entre el manguito de acero inoxidable y la línea principal debe tener al menos 6" (15 cm) de largo para permitir un fácil posicionamiento.

¿Aún necesita ayuda? Estamos aquí.

Díganos en qué necesita ayuda y encontraremos la mejor solución para usted.