G-885

Modelos

| Modelo | Descripción | Agregar a la lista |

|---|---|---|

| G-885-C-10 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 10 instalada | + |

| G-885-C-13 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 13 instalada | + |

| G-885-C-15 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 15 instalada | + |

| G-885-C-18-S | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 18 instalada | + |

| G-885-C-20 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 20 instalada | + |

| G-885-C-23-S | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 23 instalada | + |

| G-885-C-25-S | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 25 instalada | + |

| G-885-C-33 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 33 instalada | + |

| G-885-C-38 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 38 instalada | + |

| G-885-C-43 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 43 instalada | + |

| G-885-C-48-S | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 48 instalada | + |

| G-885-C-53 | Aspersor para golf G-885C, configuración de boquillas opuesta de círculo completo/parcial, tecnología Check-O-Matic, boquilla 53 instalada | + |

| G-885-D-10-P5 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 10 instalada, 3,4 bar | + |

| G-885-D-13-P5 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 13 instalada, 3,4 bar | + |

| G-885-D-15-P5 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 15 instalada, 3,4 bar | + |

| G-885-D-18-P5-S | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 18 instalada, 3,4 bar | + |

| G-885-D-18-P6 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 18 instalada, 4,5 bar | + |

| G-885-D-20-P6 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 20 instalada, 4,5 bar | + |

| G-885-D-23-P6-S | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 23 instalada, 4,5 bar | + |

| G-885-D-23-P8 | Aspersor para golf G-885D, configuración de boquillas opuestas de círculo completo/parcial, diseño de válvula en cabezal, módulo bidireccional Pilot-100 integrado, boquilla 23 instalada, 5,5 bar | + |

Create a new My List.

Especificaciones

ESPECIFICACIONES DEL MODELO

- Círculo completo real/Sector ajustable (60° a 360°)

VARIANTES DEL MODELO

| C = | Check-O-Matic aguanta hasta 8 m de desnivel y convierte rápidamente a circuitos hidráulicos normalmente abiertos mediante las conexiones superiores. |

| D = | Válvula y decodificador incorporado con todas las especificaciones "E" |

| DD = | Válvula y decodificador incorporado de 2 estaciones con todas las especificaciones "E" |

| E = | Electroválvula incorporada en el cabezal con regulador de presión ajustable, selector automático de encendido/apagado, solenoide de 210 mA (370 mA en arranque) con émbolo cautivo y purgado interno. |

ESPECIFICACIONES DE FUNCIONAMIENTO

G885

- Radio: 13,1 m a 27,7 m

- Caudal: 1,86 a 13,06 m3/h; 31 a 217,7 l/min

- Intervalo de presión: 3,4 a 6,9 bares; 344 a 689 kPa

- Presión nominal: 10 bares; 1000 kPa

Medio

Funciones

Dotado de la mayor potencia de turbina para golf existente en el mercado, el engranaje patentado de G885 impulsa todo lo que se le ponga delante. Pruébela y verá. Basta girar la torreta a mano para sentir claramente la increíble resistencia de esta turbina. Con un núcleo tan potente, una serie de eficientes boquillas, disponible en círculo completo real y parcial, la nueva G-85 es la turbina para campos de golf con la que siempre puede contar.

Añada el práctico mantenimiento completo por la parte superior (TTS) y la tecnología de decodificador incorporado (DIH), y ya no solo tiene el surtido más potente de rotores, sino que también tiene la elección más inteligente. El G-885 es realmente la siguiente generación de rotores para campos de golf, y es la opción perfecta para instalaciones nuevas, renovaciones y actualizaciones del sistema.

VENTAJAS PRINCIPALES

Funciones avanzadas

Dotado de la mayor potencia de turbina para golf existente en el mercado, el engranaje patentado de G885 impulsa todo lo que se le ponga delante. Pruébela y verá. Basta girar la torreta a mano para sentir claramente la increíble resistencia de esta turbina. Con un núcleo tan potente, una serie de eficientes boquillas y un círculo completo real con opciones para círculo parcial, la nueva G885 es la turbina para campos de golf con la que siempre puede contar.

Elija entre un amplio surtido de eficientes boquillas a prueba de viento, de trayectoria estándar de 22,5º o de trayectoria de ángulo bajo de 15º. En cualquier caso, hay una combinación perfecta para las condiciones particulares de su campo de golf y para resolver sus necesidades. Independientemente de la versión que elija, cambiar las boquillas es rápido y sencillo con la exclusiva tecnología QuickChange de Hunter.

Boquillas de trayectoria estándar de 22,5°

Boquillas de trayectoria de ángulo bajo de 15°

Con el G885, el arco se puede ajustar en cualquier momento: desinstalado, instalado o en funcionamiento. El cómodo anillo de ajuste se puede girar a mano o con la herramienta de ajuste de arco, de fácil uso. Esta herramienta combinada también se puede utilizar como medio para mantener el vástago en la posición emergente para los cambios de boquilla.

Ya sea porque quiere un poco de césped detrás de sus rotores G885 de arco ajustable o un aspecto más "modelado" del límite de la calle, aquí están las boquillas posteriores de contorno para poner en práctica su uso. Elija entre cuatro boquillas de alcance corto o cuatro boquillas de alcance medio, según lo que necesite.

Configurar su arco ajustable al aspersor G885 es rápido y sencillo. El conjunto de engranajes incorporado permite alinear el punto de inversión del lado derecho con un simple giro del vástago. El G885 también se puede transformar fácilmente a círculo completo real no reversible con nuestra exclusiva función QuickSet-360.

En casi todos los campos de golf existen problemas de riego complejos. Esto es especialmente cierto en áreas estrechas y difíciles de regar. El adaptador de boquilla principal G885 puede resolver muchos de estos problemas de forma rápida y sencilla, ya que permite mezclar y combinar las boquillas para obtener la cobertura necesaria o para usar el flujo primario por completo.

El revolucionario diseño TTS (Total Top Servicing - mantenimiento total por la parte superior) de Hunter ofrece unas funciones y ventajas únicas, que han sido desarrolladas teniendo en cuenta la innovación y un fácil mantenimiento. Haga clic AQUÍ para ver todas las características avanzadas de los sistemas TTS y por qué un sistema Hunter Golf es la elección perfecta para su campo.

Las turbinas configuradas de fábrica con decodificador integrado en el cabezal (DIH) están disponibles para todas las turbinas TTS de las series 800 y 900 con válvula en el cabezal. Todas las turbinas DIH incorporan la tecnología Total Top Programming (programación completa por la parte superior) patentada por Hunter. Ya sea en el taller o después de la instalación, la estación con decodificador se puede programar sin desmontar la turbina.

Tablas

|

G885 |

|

|---|---|

| Altura total | 30 cm |

| Altura de emergencia | 9,5 cm |

| Diámetro de la tapa | 18 cm |

| Conexión | ACME hembra 1-1/2" |

| Datos de rendimiento de las boquillas TTS-885/G-885/G-85B * - Sistema métrico | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Boquilla | Presión | RADIO | Caudal | Pluv. mm/h | |||||

| bar | kPa | m | m³/h | l/min | |||||

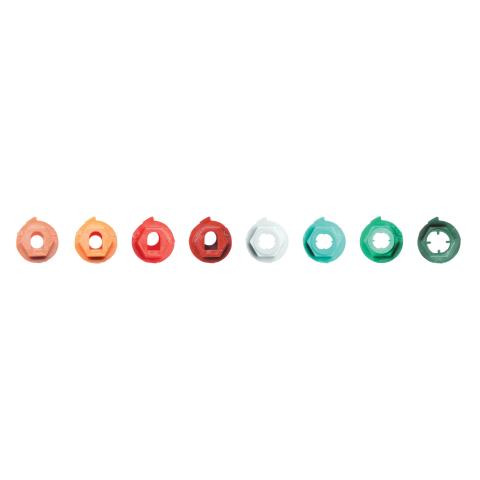

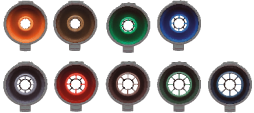

Naranja 803603 |

10 •

Verde claro

|

Verde oscuro 315312 |

3.4 | 344 | 11,3 | 2,02 | 33,7 | 15,9 | 18,4 |

| 4.1 | 413 | 11,9 | 2.23 | 37,1 | 15,8 | 18,2 | |||

| 4.5 | 450 | 12,5 | 2,32 | 38,6 | 14,8 | 17,1 | |||

| - | - | - | - | - | - | - | |||

| - | - | - | - | - | - | - | |||

Naranja 803603 |

13 •

Azul claro

|

Blanco 315314 |

3.4 | 344 | 14,3 | 2,59 | 43,2 | 12,6 | 14,6 |

| 4.1 | 413 | 14,6 | 2,79 | 46,6 | 13,1 | 15,1 | |||

| 4.5 | 450 | 14,9 | 2,93 | 48,8 | 13,1 | 15,2 | |||

| - | - | - | - | - | - | - | |||

| - | - | - | - | - | - | - | |||

Naranja 803603 |

15 •

Blanco

|

Blanco 315314 |

3.4 | 344 | 15,9 | 2,93 | 48,8 | 11,7 | 13,5 |

| 4.1 | 413 | 15,9 | 3,29 | 54,9 | 13,1 | 15,1 | |||

| 4.5 | 450 | 16,2 | 3,38 | 56,4 | 13 | 15 | |||

| 4.8 | 482 | 16,2 | 3.52 | 58,7 | 13,5 | 15,6 | |||

| 5.5 | 551 | 16,5 | 3,75 | 62,5 | 13,8 | 16,0 | |||

Naranja 803603 |

18 •

Naranja

|

Verde claro 315313 |

3.4 | 344 | 17,4 | 3,77 | 62,8 | 12,5 | 14,4 |

| 4.1 | 413 | 17,7 | 4,04 | 67,4 | 12,9 | 14,9 | |||

| 4.5 | 450 | 18 | 4,23 | 70,4 | 13,1 | 15,1 | |||

| 4.8 | 482 | 18,3 | 4,41 | 73,4 | 13,2 | 15,2 | |||

| 5.5 | 551 | 18,6 | 4.66 | 77,6 | 13,5 | 15,6 | |||

Naranja 803603 |

20 •

Ocre

|

Verde claro 315313 |

3.4 | 344 | 18 | 4,07 | 67,8 | 12,6 | 14,5 |

| 4.1 | 413 | 18,6 | 4.43 | 73,8 | 12,8 | 14,8 | |||

| 4.5 | 450 | 18,9 | 4,50 | 75 | 12,6 | 14,5 | |||

| 4.8 | 482 | 19,2 | 4,68 | 78 | 12,7 | 14,7 | |||

| 5.5 | 551 | 19,5 | 5,02 | 83,7 | 13,2 | 15,2 | |||

Naranja 803603 |

23 •

Verde

|

Verde claro 315313 |

3.4 | 344 | 19,8 | 4,59 | 76,5 | 11,7 | 13,5 |

| 4.1 | 413 | 20,1 | 5,02 | 83,7 | 12,4 | 14,3 | |||

| 4.5 | 450 | 20,4 | 5,43 | 90,5 | 13 | 15 | |||

| 4.8 | 482 | 20,4 | 5,50 | 91,6 | 13,2 | 15,2 | |||

| 5.5 | 551 | 21 | 5,88 | 98 | 13,3 | 15,4 | |||

Rojo 803602 |

25 •

Azul

|

Verde 315310 |

4.5 | 450 | 21,6 | 6.43 | 107,1 | 13,7 | 15,8 |

| 4.8 | 482 | 21,9 | 6,66 | 110,9 | 13,8 | 16,0 | |||

| 5.5 | 551 | 22,3 | 7,16 | 119,2 | 14,5 | 16,7 | |||

| 6,2 | 620 | 22,6 | 7,59 | 126,4 | 14,9 | 17,2 | |||

| 6,9 | 689 | 22,9 | 8,04 | 134 | 15,4 | 17,8 | |||

Rojo 803602 |

33 •

Gris

|

Verde 315310 |

4.5 | 450 | 21,9 | 6,95 | 115,8 | 14,4 | 16,7 |

| 4.8 | 482 | 22,3 | 7,18 | 119,6 | 14,5 | 16,7 | |||

| 5.5 | 551 | 22,9 | 7,70 | 128,3 | 14,7 | 17,0 | |||

| 6,2 | 620 | 23,5 | 8,13 | 135,5 | 14,8 | 17,0 | |||

| 6,9 | 689 | 24,1 | 8,61 | 143,5 | 14,8 | 17,1 | |||

Rojo 803602 |

38 •

Rojo

|

Verde 315310 |

4.5 | 450 | 23,2 | 7,93 | 132,1 | 14,8 | 17,1 |

| 4.8 | 482 | 23,8 | 8,22 | 137 | 14,5 | 16,8 | |||

| 5.5 | 551 | 24,4 | 8,88 | 148 | 14,9 | 17,2 | |||

| 6,2 | 620 | 25 | 9,36 | 156 | 15 | 17,3 | |||

| 6,9 | 689 | 25,6 | 9,88 | 164,7 | 15,1 | 17,4 | |||

Rojo 803602 |

43 •

Marrón oscuro

|

Verde 315310 |

- | - | - | - | - | - | - |

| 4.8 | 482 | 24,7 | 9,36 | 156 | 15,4 | 17,7 | |||

| 5.5 | 551 | 25,3 | 9,88 | 164,7 | 15,4 | 17,8 | |||

| 6,2 | 620 | 26,2 | 10,49 | 174,9 | 15,3 | 17,6 | |||

| 6,9 | 689 | 27,1 | 11,06 | 184,3 | 15 | 17,4 | |||

Rojo oscuro 803601 |

48 •

Verde oscuro

|

Verde oscuro 315312 |

- | - | - | - | - | - | - |

| 4.8 | 482 | 25,3 | 10,52 | 175,3 | 16,4 | 19 | |||

| 5.5 | 551 | 25,9 | 10,99 | 183,2 | 16,4 | 18,9 | |||

| 6,2 | 620 | 27,1 | 11,74 | 195,7 | 16,0 | 18,4 | |||

| 6,9 | 689 | 27,7 | 12,38 | 206,3 | 16,1 | 18,6 | |||

Rojo oscuro 803601 |

53 •

Azul oscuro

|

Verde oscuro 315312 |

- | - | - | - | - | - | - |

| 4.8 | 482 | 26,5 | 11,52 | 191,9 | 16,4 | 18,9 | |||

| 5.5 | 551 | 27,1 | 12,06 | 201 | 16,4 | 18,9 | |||

| 6,2 | 620 | 28 | 12,81 | 213,5 | 16,3 | 18,8 | |||

| 6,9 | 689 | 28,7 | 13,54 | 225,6 | 16,5 | 19 | |||

|

Nota: Tapón de la boquilla ref. 315300 instalado en la parte posterior del orificio para la boquilla. |

|||||||||

| Ref. | Color | Perfil | 4,5 bares | 5,5 bares | ||

|---|---|---|---|---|---|---|

| Metros | l/m | Metros | l/m | |||

| 803604 | Melocotón | 7.6 | 12,9 | 8.2 | 14,8 | |

| 803603 | Naranja | 8.5 | 14,4 | 8,8 | 15,9 | |

| 803602 | Rojo | 9,4 | 15,9 | 10.1 | 17,0 | |

| 803601 | Rojo oscuro | 10.4 | 17,4 | 11,0 | 18,5 | |

| 315314 | Blanco | 11,3 | 10,6 | 11,6 | 11,0 | |

| 315313 | Verde claro | 12,8 | 16,3 | 13,4 | 17,8 | |

| 315310 | Verde | 14,0 | 19,7 | 14,6 | 21,6 | |

| 315312 | Verde oscuro | 14,9 | 29,9 | 15,5 | 33,3 | |

BOQUILLAS POSTERIORES DE CONTORNO

Documentos

Seleccione el tipo

- Todos los documentos

- Manuales

- Marketing

- Especificaciones

- Piezas de recambio

Photos

Fotos de estudio

Descargar imagen

Medio Original

Descargar imagen

Medio Original

Descargar imagen

Medio Original

Descargar imagen

Medio Original

Descargar imagen

Medio Original