OFF

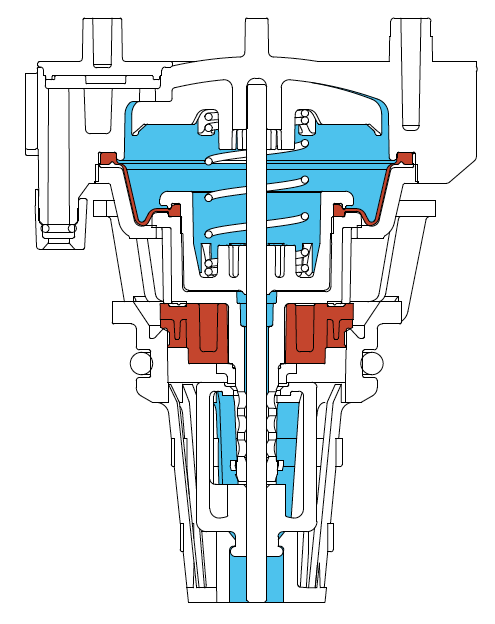

Water enters through valve filter screen and pressure holds the diaphragm closed.

ON

Pressure vents through the selector switch manifold, which allows the inlet valve diaphragm to open and water to flow up to the riser and nozzle.

1. Turn off main water supply and inlet/ outlet valve on interior mounted backflow devices.

TIP: Tag these valves so they are not inadvertently opened during freezing temperatures.

2. Turn off power to pump(s).

3. Open any drains on the water source and pump(s) and leave them open.

4. Remove exterior water meters and backflow devices if required.

5. Open any drain valves and quick couplers in low points of the system. This allows water to drain from the piping and reduces the time required for system blowout.

6. Open high points in the system (including quick couplers if applicable) to allow air into the system.

1. Connect the compressor to the irrigation system at the designated point of connection. If this is not available, the correct compressor fitting must be installed. To avoid damage to the piping system due to overheating, the use galvanized pipe to dissipate heat prior to entering the irrigation system is recommended.

2. Avoid blowing air through water meters, flow sensors, and backflow devices; the air connection should be downstream of these items.

NOTE: This procedure should be performed by a licensed contractor only. Always wear proper PPE; compressed air can cause serious injury including eye injury from flying debris. Avoid standing over any irrigation components (e.g.,sprinklers, valves, piping) while using compressed air in the system.

1. Open a zone and/or quick coupler(s).

2. Ensure air supply hoses are properly connected to the air compressor fittings on the irrigation system.

3. Start the compressor and open the air supply valve on compressor slowly to begin introducing compressed air into the system.

4. Regulate air pressure so the maximum pressure does not exceed the rating of the weakest component in the system. Volume, measured in cubic feet per minute (CFM) or cubic meters per minute (m³/min), is more important than pressure to displace water in the system.

5. Once mostly air is coming from any open drains and/or quick couplers, they may be closed.

NOTE: Always ensure that a zone or quick coupler is open at all times when compressed air is moving through the irrigation system.

6. Activate each zone manually from the controller to evacuate water. Once only a very fine mist is coming out of each sprinkler head on the zone, move to the next zone. Avoid prolonged running of zones that are dry to avoid damaging sprinklers.

7. Repeat the process running through each zone a second time to confirm all water is removed from the system.

8. Turn off the air supply with the last zone still running. Allow the pressure to completely expel before disconnecting air hoses.

9. Close any open drains and remove any quick coupler keys from the system. Make sure there are no points of entry for debris to enter the system.

Still need help? We're here.

Tell us what you need support with and we'll find the best solution for you.