I-40

- Durable: Stainless steel riser built to withstand tough conditions

- Accurate: Triple nozzle system provides uniform, wind-resistant distribution

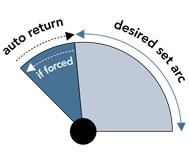

- Reliable: Automatic arc return and non-strippable drive ensures dependability

Filter

Pop-up Height

Arc Option

Radius

Nozzle Type

Flow Rate

Inlet Size

Inlet Type

Outlet Type

Outlet Style

Lay Length

Nozzle Option

Emitter Spacing

Coil Length

| Model | Description | Add to List |

|---|---|---|

| I-40-04-SS | I-40 Rotor, 10 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, six nozzles included | + |

| I-40-04-SS-HS | I-40 Rotor, 10 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, high-speed, six nozzles included | + |

| I-40-04-SS-HS-R | I-40 Rotor, 10 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, high-speed, reclaimed ID, six nozzles included | + |

| I-40-04-SS-ON | I-40 Rotor, 10 cm, full-circle, with opposing nozzle, 1" (25 mm) inlet, stainless steel riser, check valve, six nozzles included | + |

| I-40-04-SS-ON-R | I-40 Rotor, 10 cm, full-circle, with opposing nozzle, 1" (25 mm) inlet, stainless steel riser, check valve, reclaimed ID, six nozzles included | + |

| I-40-04-SS-R | I-40 Rotor, 10 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, reclaimed ID, six nozzles included | + |

| I-40-06-SS | I-40 Rotor, 15 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, six nozzles included | + |

| I-40-06-SS-HS | I-40 Rotor, 15 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, high-speed, six nozzles included | + |

| I-40-06-SS-HS-R | I-40 Rotor, 15 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, high-speed, reclaimed ID, six nozzles included | + |

| I-40-06-SS-ON | I-40 Rotor, 15 cm, full-circle, with opposing nozzle, 1" (25 mm) inlet, stainless steel riser, check valve, six nozzles included | + |

| I-40-06-SS-ON-R | I-40 Rotor, 15 cm, full-circle, with opposing nozzle, 1" (25 mm) inlet, stainless steel riser, check valve, reclaimed ID, six nozzles included | + |

| I-40-06-SS-R | I-40 Rotor, 15 cm, adjustable from 50° to 360°, 1" (25 mm) inlet, stainless steel riser, check valve, reclaimed ID, six nozzles included | + |

Create a new My List.

Contact your local distributor for product availability and ordering.

Specifications

Operating Specifications

- Nozzle choices: 12

- Radius I-40: 13.1 to 21.3 m

- Radius I-40-ON: 15.2 to 23.2 m

- Flow I-40: 1.63 to 6.84 m3/hr; 27.2 to 114.1 l/min

- Flow I-40-ON: 2.75 to 7.76 m3/hr; 45.8 to 129.4 l/min

- Recommended pressure range: 2.5 to 7.0 bar; 250 to 700 kPa

- Operating pressure range: 2.5 to 7.0 bar; 250 to 700 kPa

- Precipitation rates: 15 mm/hr approximately

- Nozzle trajectory: standard = 25°

- Warranty period: 5 years

Factory-Installed Options

- Reclaimed water ID

- High-speed rotation

User-Installed Options

- HSJ-1 prefabricated 1" (25 mm) PVC Swing Joint

Features

The I-40 is a tough commercial rotor that delivers water with accuracy and efficiency at distances up to 23.2 m. Featuring diverse three-port nozzle options, a non-strippable drive, and a thick rubber cover built to prevent injury, it's no wonder this rotor is found in more stadiums than any other in the world. With the strength of stainless steel, the I-40 is built to last in the harshest sports fields, public parks, and commercial environments. If efficiency, effective irrigation, and beautiful results are the goal, the I-40 is the irrigation professional's best solution.

Key Benefits

Advanced Features

The opposing nozzle design offers excellent water distribution. With primary and secondary nozzles on opposing sides of the turret, streams arc in opposite directions as the sprinkler rotates for outstanding mid-range and close-in watering.

This patented feature returns the turret to the original arc regardless of where it is turned. This ensures vandal protection in any environment.

The patented, non-strippable, vandal proof drive mechanism enables the turret to be turned without causing damage.

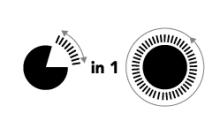

Patented non-reversing 360 for part- and full-circle in one model, from 50 to 360 degrees.

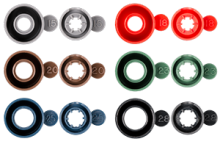

Nozzles are easier to differentiate in the field for quick reference and simple installation.

Purple caps indicate where non-potable irrigation water is being used.

For unforgiving soil conditions, unpredictable climates, or heavy foot traffic, stainless steel is the best choice

As air in the system piping can cause long-term damage to rotors and plumbing, the drain check valve keeps lines from draining when the system is shut off. This saves water, reduces liability, and increases system life.

Charts

| I-40 Nozzle Performance Data | |||||||

|---|---|---|---|---|---|---|---|

| Nozzle | Pressure | Radius | Flow | Precip mm/hr | |||

| bar | kPa | m | m³/hr | l/min | |||

| 8 •

(40) Lt. Brown

|

2.5 | 250 | 13.1 | 1.63 | 27.2 | 19 | 22 |

| 3.0 | 300 | 13.4 | 1.80 | 30.0 | 20 | 23 | |

| 3.5 | 350 | 13.7 | 1.94 | 32.3 | 21 | 24 | |

| 4.0 | 400 | 14.0 | 2.06 | 34.4 | 21 | 24 | |

| 4.5 | 450 | 14.0 | 2.18 | 36.3 | 22 | 26 | |

| 5.0 | 500 | 14.3 | 2.29 | 38.2 | 22 | 26 | |

| 5.5 | 550 | 14.6 | 2.41 | 40.2 | 23 | 26 | |

| 10 •

(41) Lt. Green

|

3.0 | 300 | 14.6 | 2.20 | 36.6 | 21 | 24 |

| 3.5 | 350 | 14.9 | 2.37 | 39.4 | 21 | 24 | |

| 4.0 | 400 | 15.2 | 2.52 | 42.0 | 22 | 25 | |

| 4.5 | 450 | 15.5 | 2.67 | 44.5 | 22 | 25 | |

| 5.0 | 500 | 15.5 | 2.81 | 46.8 | 23 | 27 | |

| 5.5 | 550 | 15.8 | 2.96 | 49.3 | 24 | 27 | |

| 6.0 | 600 | 16.2 | 3.08 | 51.4 | 24 | 27 | |

| 13 •

(42) Lt. Blue

|

3.0 | 300 | 14.9 | 2.36 | 39.4 | 21 | 24 |

| 3.5 | 350 | 15.2 | 2.55 | 42.6 | 22 | 25 | |

| 4.0 | 400 | 15.5 | 2.73 | 45.5 | 23 | 26 | |

| 4.5 | 450 | 15.5 | 2.90 | 48.3 | 24 | 28 | |

| 5.0 | 500 | 15.8 | 3.06 | 51.0 | 24 | 28 | |

| 5.5 | 550 | 16.2 | 3.23 | 53.9 | 25 | 29 | |

| 6.0 | 600 | 16.5 | 3.38 | 56.3 | 25 | 29 | |

| 15 •

(43) Grey

|

3.0 | 300 | 16.2 | 2.93 | 48.8 | 22 | 26 |

| 3.5 | 350 | 16.5 | 3.19 | 53.2 | 24 | 27 | |

| 4.0 | 400 | 16.8 | 3.44 | 57.3 | 24 | 28 | |

| 4.5 | 450 | 17.1 | 3.67 | 61.2 | 25 | 29 | |

| 5.0 | 500 | 17.4 | 3.89 | 64.9 | 26 | 30 | |

| 5.5 | 550 | 18.0 | 4.14 | 68.9 | 26 | 30 | |

| 6.0 | 600 | 18.3 | 4.34 | 72.4 | 26 | 30 | |

| 6.2 | 650 | 18.3 | 4.43 | 73.8 | 26 | 31 | |

| 23 •

(44) Dk. Green

|

3.5 | 350 | 18.6 | 4.48 | 74.6 | 26 | 30 |

| 4.0 | 400 | 18.9 | 4.76 | 79.4 | 27 | 31 | |

| 4.5 | 450 | 19.2 | 5.03 | 83.9 | 27 | 32 | |

| 5.0 | 500 | 19.5 | 5.29 | 88.1 | 28 | 32 | |

| 5.5 | 550 | 19.8 | 5.56 | 92.7 | 28 | 33 | |

| 6.0 | 600 | 20.1 | 5.79 | 96.5 | 29 | 33 | |

| 6.2 | 620 | 20.1 | 5.89 | 98.1 | 29 | 34 | |

| 6.5 | 650 | 20.1 | 6.01 | 100.2 | 30 | 34 | |

| 6.9 | 690 | 20.4 | 6.19 | 103.2 | 30 | 34 | |

| 25 •

(45) Dk. Blue

|

3.5 | 350 | 19.8 | 4.98 | 83.0 | 25 | 29 |

| 4.0 | 400 | 20.1 | 5.33 | 88.7 | 26 | 30 | |

| 4.5 | 450 | 20.4 | 5.65 | 94.2 | 27 | 31 | |

| 5.0 | 500 | 20.7 | 5.96 | 99.3 | 28 | 32 | |

| 5.5 | 550 | 21.0 | 6.29 | 104.9 | 28 | 33 | |

| 6.0 | 600 | 21.0 | 6.57 | 109.6 | 30 | 34 | |

| 6.2 | 620 | 21.0 | 6.69 | 111.5 | 30 | 35 | |

| 6.5 | 650 | 21.3 | 6.84 | 114.1 | 30 | 35 | |

| 6.9 | 690 | 21.3 | 7.07 | 117.8 | 31 | 36 | |

|

Notes: |

|||||||

| I-40 High Speed Nozzle Performance Data | |||||||

|---|---|---|---|---|---|---|---|

| Nozzle | Pressure | Radius | Flow | Precip mm/hr | |||

| bar | kPa | m | m³/hr | l/min | |||

| 8 •

(40) Lt. Brown

|

2.5 | 250 | 12.2 | 1.63 | 27.2 | 22 | 25 |

| 3.0 | 300 | 12.5 | 1.80 | 30.0 | 23 | 27 | |

| 3.5 | 350 | 12.8 | 1.94 | 32.3 | 24 | 27 | |

| 4.0 | 400 | 12.8 | 2.06 | 34.4 | 25 | 29 | |

| 4.5 | 450 | 13.1 | 2.18 | 36.3 | 25 | 29 | |

| 5.0 | 500 | 13.4 | 2.29 | 38.2 | 25 | 29 | |

| 5.5 | 550 | 13.4 | 2.41 | 40.2 | 27 | 31 | |

| 10 •

(41) Lt. Green

|

3.0 | 300 | 13.4 | 2.20 | 36.6 | 24 | 28 |

| 3.5 | 350 | 13.7 | 2.37 | 39.4 | 25 | 29 | |

| 4.0 | 400 | 14.0 | 2.52 | 42.0 | 26 | 30 | |

| 4.5 | 450 | 14.0 | 2.67 | 44.5 | 27 | 31 | |

| 5.0 | 500 | 14.3 | 2.81 | 46.8 | 27 | 32 | |

| 5.5 | 550 | 14.6 | 2.96 | 49.3 | 28 | 32 | |

| 6.0 | 600 | 14.6 | 3.08 | 51.4 | 29 | 33 | |

| 13 •

(42) Lt. Blue

|

3.0 | 300 | 13.7 | 2.36 | 39.4 | 25 | 29 |

| 3.5 | 350 | 14.0 | 2.55 | 42.6 | 26 | 30 | |

| 4.0 | 400 | 14.3 | 2.73 | 45.5 | 27 | 31 | |

| 4.5 | 450 | 14.3 | 2.90 | 48.3 | 28 | 33 | |

| 5.0 | 500 | 14.6 | 3.06 | 51.0 | 29 | 33 | |

| 5.5 | 550 | 14.9 | 3.23 | 53.9 | 29 | 33 | |

| 6.0 | 600 | 14.9 | 3.38 | 56.3 | 30 | 35 | |

| 15 •

(43) Grey

|

3.0 | 300 | 15.2 | 2.93 | 48.8 | 25 | 29 |

| 3.5 | 350 | 15.5 | 3.19 | 53.2 | 26 | 30 | |

| 4.0 | 400 | 15.8 | 3.44 | 57.3 | 27 | 32 | |

| 4.5 | 450 | 15.8 | 3.67 | 61.2 | 29 | 34 | |

| 5.0 | 500 | 16.2 | 3.89 | 64.9 | 30 | 34 | |

| 5.5 | 550 | 16.5 | 4.14 | 68.9 | 31 | 35 | |

| 6.0 | 600 | 16.5 | 4.34 | 72.4 | 32 | 37 | |

| 6.2 | 620 | 16.5 | 4.43 | 73.8 | 33 | 38 | |

| 23 •

(44) Dk. Green

|

3.5 | 350 | 16.8 | 4.48 | 74.6 | 32 | 37 |

| 4.0 | 400 | 17.4 | 4.76 | 79.4 | 32 | 36 | |

| 4.5 | 450 | 17.7 | 5.03 | 83.9 | 32 | 37 | |

| 5.0 | 500 | 17.7 | 5.29 | 88.1 | 34 | 39 | |

| 5.5 | 550 | 18.0 | 5.56 | 92.7 | 34 | 40 | |

| 6.0 | 600 | 18.3 | 5.79 | 96.5 | 35 | 40 | |

| 6.2 | 620 | 18.6 | 5.89 | 98.1 | 34 | 39 | |

| 6.5 | 650 | 18.6 | 6.01 | 100.2 | 35 | 40 | |

| 6.9 | 690 | 18.6 | 6.19 | 103.2 | 36 | 41 | |

| 25 •

(45) Dk. Blue

|

3.5 | 350 | 17.4 | 4.98 | 83.0 | 33 | 38 |

| 4.0 | 400 | 18.0 | 5.33 | 88.7 | 33 | 38 | |

| 4.5 | 450 | 18.3 | 5.65 | 94.2 | 34 | 39 | |

| 5.0 | 500 | 18.6 | 5.96 | 99.3 | 34 | 40 | |

| 5.5 | 550 | 18.9 | 6.29 | 104.9 | 35 | 41 | |

| 6.0 | 600 | 19.2 | 6.57 | 109.6 | 36 | 41 | |

| 6.2 | 620 | 19.5 | 6.69 | 111.5 | 35 | 41 | |

| 6.5 | 650 | 19.5 | 6.84 | 114.1 | 36 | 42 | |

| 6.9 | 690 | 19.5 | 7.07 | 117.8 | 37 | 43 | |

|

Notes: |

|||||||

| I-40 Dual Opposing Nozzle Performance Data |

|||||||

|---|---|---|---|---|---|---|---|

| Nozzle | Pressure | Radius | Flow | Precip mm/hr | |||

| bar | kPa | m | m³/hr | l/min | |||

| 15 •

Grey

|

3.0 | 300 | 15.2 | 2.75 | 45.8 | 12 | 14 |

| 3.5 | 350 | 15.8 | 2.91 | 48.5 | 12 | 13 | |

| 4.0 | 400 | 16.2 | 3.06 | 51.0 | 12 | 14 | |

| 4.5 | 450 | 16.8 | 3.20 | 53.3 | 11 | 13 | |

| 5.0 | 500 | 17.1 | 3.32 | 55.4 | 11 | 13 | |

| 5.5 | 550 | 17.4 | 3.46 | 57.7 | 11 | 13 | |

| 6.0 | 600 | 17.7 | 3.58 | 59.6 | 11 | 13 | |

| 6.2 | 620 | 17.7 | 3.62 | 60.4 | 12 | 13 | |

| 18 •

Red

|

3.0 | 300 | 17.4 | 2.90 | 48.3 | 10 | 11 |

| 3.5 | 350 | 17.7 | 3.15 | 52.5 | 10 | 12 | |

| 4.0 | 400 | 18.0 | 3.38 | 56.4 | 10 | 12 | |

| 4.5 | 450 | 18.0 | 3.61 | 60.1 | 11 | 13 | |

| 5.0 | 500 | 18.3 | 3.82 | 63.7 | 11 | 13 | |

| 5.5 | 550 | 18.9 | 4.05 | 67.5 | 11 | 13 | |

| 6.0 | 600 | 19.2 | 4.25 | 70.8 | 12 | 13 | |

| 6.2 | 620 | 19.2 | 4.33 | 72.1 | 12 | 14 | |

| 6.5 | 650 | 19.5 | 4.43 | 73.9 | 12 | 13 | |

| 20 •

Dk. Brown

|

3.5 | 350 | 18.3 | 3.98 | 66.2 | 12 | 14 |

| 4.0 | 400 | 18.9 | 4.26 | 71.1 | 12 | 14 | |

| 4.5 | 450 | 19.2 | 4.54 | 75.6 | 12 | 14 | |

| 5.0 | 500 | 19.5 | 4.80 | 80.0 | 13 | 15 | |

| 5.5 | 550 | 20.1 | 5.08 | 84.7 | 13 | 15 | |

| 6.0 | 600 | 19.8 | 5.32 | 88.7 | 14 | 16 | |

| 6.2 | 620 | 19.8 | 5.42 | 90.4 | 14 | 16 | |

| 6.5 | 650 | 20.1 | 5.55 | 92.5 | 14 | 16 | |

| 6.9 | 690 | 20.1 | 5.74 | 95.7 | 14 | 16 | |

| 23 •

Dk. Green

|

3.5 | 350 | 18.9 | 4.23 | 70.6 | 12 | 14 |

| 4.0 | 400 | 19.5 | 4.55 | 75.8 | 12 | 14 | |

| 4.5 | 450 | 19.8 | 4.85 | 80.8 | 12 | 14 | |

| 5.0 | 500 | 20.1 | 5.14 | 85.6 | 13 | 15 | |

| 5.5 | 550 | 20.4 | 5.45 | 90.8 | 13 | 15 | |

| 6.0 | 600 | 20.7 | 5.71 | 95.1 | 13 | 15 | |

| 6.2 | 620 | 20.7 | 5.82 | 97.0 | 14 | 16 | |

| 6.5 | 650 | 20.7 | 5.96 | 99.4 | 14 | 16 | |

| 6.9 | 690 | 21.0 | 6.17 | 102.9 | 14 | 16 | |

| 25 •

Dk. Blue

|

3.5 | 350 | 19.5 | 4.60 | 76.7 | 12 | 14 |

| 4.0 | 400 | 20.1 | 4.92 | 82.1 | 12 | 14 | |

| 4.5 | 450 | 20.4 | 5.23 | 87.2 | 13 | 14 | |

| 5.0 | 500 | 20.7 | 5.52 | 92.0 | 13 | 15 | |

| 5.5 | 550 | 21.0 | 5.84 | 97.3 | 13 | 15 | |

| 6.0 | 600 | 21.3 | 6.10 | 101.7 | 13 | 15 | |

| 6.2 | 620 | 21.3 | 6.22 | 103.6 | 14 | 16 | |

| 6.5 | 650 | 21.3 | 6.36 | 106.0 | 14 | 16 | |

| 6.9 | 690 | 21.6 | 6.57 | 109.5 | 14 | 16 | |

| 28 •

Black

|

3.5 | 350 | 19.8 | 5.73 | 95.5 | 15 | 17 |

| 4.0 | 400 | 20.4 | 6.07 | 101.1 | 15 | 17 | |

| 4.5 | 450 | 21.0 | 6.38 | 106.4 | 14 | 17 | |

| 5.0 | 500 | 21.3 | 6.68 | 111.3 | 15 | 17 | |

| 5.5 | 550 | 21.9 | 7.00 | 116.7 | 15 | 17 | |

| 6.0 | 600 | 22.3 | 7.27 | 121.1 | 15 | 17 | |

| 6.2 | 620 | 22.3 | 7.38 | 122.9 | 15 | 17 | |

| 6.5 | 650 | 22.6 | 7.52 | 125.3 | 15 | 17 | |

| 6.9 | 690 | 23.2 | 7.73 | 128.8 | 14 | 17 | |

|

Note: |

|||||||

Documents

Select Type

- All Documents

- Manuals

- Marketing

- Specifications

- Replacement Parts

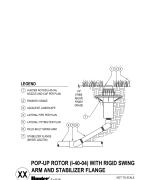

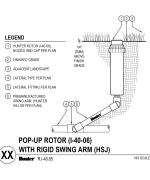

| I-40-04 - Pop-Up Rotor with Rigid Swing Arm | DWG | DXF | ||

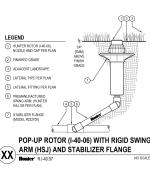

| I-40-04 - Pop-Up Rotor with Rigid Swing Arm (HSJ) | DWG | DXF | ||

| I-40-04 - Pop-Up Rotor with Rigid Swing Arm (HSJ) and Stabilizer Flange | DWG | DXF | ||

| I-40-04 - Pop-Up Rotor with Rigid Swing Arm and Stabilizer Flange | DWG | DXF | ||

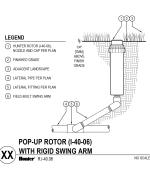

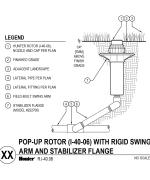

| I-40-06 with HSJ swing arm | DWG | DXF | ||

| I-40-06 with HSJ swing arm and stabilizer | DWG | DXF | ||

| I-40-06 with Swing Arm | DWG | DXF | ||

| I-40-06 with swing arm and stabilizer flange | DWG | DXF |

Support

Training

Hunter's I-Series Rotors have been the industry's leading 3/4" and 1" commercial sprinklers for many years. Recent upgrades continue to lead the industry in durability and performance.

This course covers the features and benefits of Hunter rotors for larger areas.

Photos

Application Photos

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium OriginalStudio Photos

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original

Download Image

Medium Original